What are the Appropriate Uses for Protective Equipment–Portable

What are the Right Uses of Protective Equipment?

What are the appropriate uses for protective equipment? In the current high-paced workplace, safety is not only an issue of compliance, but it is a fundamental obligation. One should learn how to act towards protective equipment to maintain the safety of employees, patients, and other professionals in other industries. Protective equipment may also be referred to as personal protective equipment (PPE) and is the first line of defence against occupational risk, which may be chemical, biological, mechanical, or other environmental hazards.

Protective equipment falls under a very broad category of equipment that is intended to reduce exposure to risks. The PPE, such as safety helmets and goggles, gloves, masks, and full body suits, is all considered part of the PPE depending on the type of risk involved in the workplace. Close monitoring of the usage is to be carried out because the best in the line of defense equipment is not worth the money. Protective Equipment may be of the following kind:

- Respiratory Protection: Masks, respirators, and ventilators to protect against airborne pollutants or dust, or infectious agents.

- Hands and Arms: Cut-resistant gloves, latex, Nitrile, and gloves that are required in laboratories, health, and industry.

- Eye and Face Protection: Face shield, eye and safety glasses to prevent injury of the face, eyes, and exposure to pathogens and remove chemical splashes, and debris injury.

- Hearing Protection: Earplugs and ear muffs to be used in noisy places of work like manufacturing factories and during construction sites.

- Protective Clothing: High visibility vests, chemical-resistant work suits, flame-resistant workplace clothes, depending on the hazards in the workplace.

- Foot Protection: Safety footwear and anti-slip shoes to prevent injuries caused by falling objects, chemicals, or uneven floors.

- Complete Body Protection: Hazmat suits and coveralls: High risk, chemical, biological, or industrial.

Greetmed Protective Equipment is the place where you can find more information about high-quality protective equipment.

Significance of the Proper Wearing of Protective Equipment

One should know how to operate the safety equipment to prevent accidents, diseases, and workplace injuries. PPE is a barrier between the hazards and the human body in case they are applied adequately. The most common reasons for PPE failures are:

- Incorrect fitting or sizing

- Putting the equipment that is not relevant to potential dangers into use.

- Poor maintenance or cleaning.

- Negligence in procedures or safety in the workplace.

The application of the safety procedures in the utilization of protective gear will ensure that the purpose is completed. As an example, PPE used in the infection control system in healthcare facilities, such as masks, gloves, and gowns, aids in the prevention of transmission of contagious diseases. Physical and chemical damage is prevented in the industries using hazardous equipment to ensure the safety of the environment, like helmets, gloves, and chemical-resistant suits.

Instructions on the Use of Protective Gear

To make PPE as effective as possible, one will have to adhere to the requirements of the PPE use and the regulations of the prosthetic equipment usage in workplaces. Here's a detailed guide:

- Risk Assessment

Before settling on PPE, the potential work-related hazards must be well evaluated. Determine the proper equipment by determining chemical, biological, physical, and ergonomic risks.

- Proper Selection

Choose industry-regulated and standards-producing PPE. This is exemplified by the fact that where there is chemical work, gloves that are not solubility would be required, and where there is high noise, certified ear protection should be on the workers.

- Correct Fitting

Ensure that PPE fits correctly. Poorly fitting gloves or misfitting masks can destroy safety.

- Training and Usage

The employees should be given training on the use of the protective equipment. This entails the process of putting on and taking off, inspection, and emergency procedures.

- Maintenance and Storage

Washing, checking, and proper storage are routine and enhance the time of PPE. To take an example, respirators, reusable gloves, and goggles can be stored in airtight containers or disinfected, respectively.

- Compliance Monitoring

The compliance with the safety guidelines on the use of protective equipment and the reduction of accidents at the workplace is maintained with the help of safety checks and regular audits.

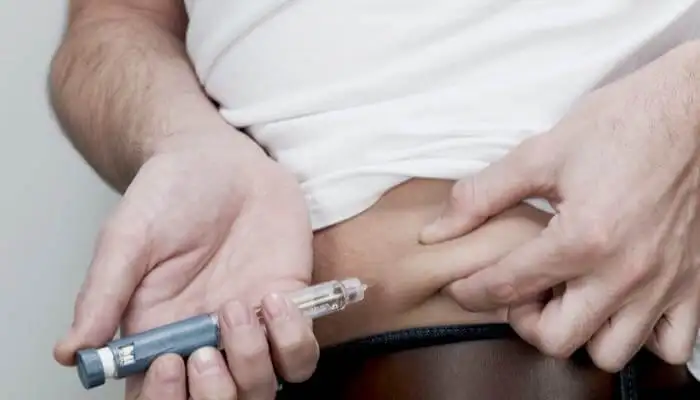

Appropriate PPE in the Healthcare

Special issues are faced by the work of medical workers, which require rigid rules of PPE. PPE is essential to healthcare workers because it prevents them from being exposed to infectious agents like bacteria, viruses, and bloodborne pathogens. Common PPE includes:

- N95 respirators and surgical masks.

- Disposable gloves and gowns

- Eye masks or eye goggles.

- Shoe covers and head caps

PPE use can be used correctly; namely, the compliance and rules of wearing PPE, such as the CDC and WHO guidelines, can be applied to ensure proper infection control. Hand hygiene should also be considered a habit of healthcare workers, as they must practice hand hygiene before and after donning PPE to ensure the risk of cross-contamination is reduced.

Industrial Protective Equipment Use

Physical and chemical hazards are numerous in manufacturing plants, construction, or other industrial environments. The appropriate wearing of PPE prevents injuries and improves working conditions. Examples include:

- Helmets are used to prevent injury from falling objects on the head.

- A wearable that is conspicuous in an area with traffic.

- Metal cutting or wood cutting. Cut-resistant gloves.

- Laboratory or chemical plants Chemical Chemical-resistant suit.

In the face of occupational safety equipment measures, the industries will enjoy a safer working population and will avoid the lost time in the face of accidents.

Conclusion

What are the appropriate uses for protective equipment? Being a reliable, convenient, and precise instrument that may be applied both on a personal and professional level, the Arm Type Full Automatic Electronic Blood Pressure Monitor is an effective device. It is its long-life span, anti-shake feature, and its long-lasting construction that make this monitor dependable in terms of performance, and it can take preventive measures regarding the health of users. Visit Greetmed.

Submit Your Request

Recent Posts

Tags

- Adult Diapers

- Are custom medical devices safe

- Baby Diapers

- Can respiratory anesthesia be used

- Digital Healthcare

- Do you offer customized consumables

- European Market

- How do you take care of a skin wound

- Industry Trends

- Lady Sanitary Napkins

- Medical Devices

- OEM Medical Devices

- Product Introductions

- Protective Equipment

- Under Pads

- What are custom-made medical devices

- What are diagnostic products

- What are hospital dressing products

- What are medical tube catheters

- What are some common protective equipment

- What are the appropriate applications for hospital dressing products

- What are the appropriate uses for protective equipment

- What is a gynecological examination

- What is a medical consumable

- What is an anesthesia kit

- What is an OEM in medical devices

- what is an wound skin care

- what is can disposable ultrasonic diagnostic

- What is good manufacturing medical devices

- What is hospital-grade protective equipment

- what is medical equipments hospital furniture

- What is medical sterilization wrapping

- What is rehabilitation equipment device

- What medical consumables do you supply

- Where can I find laboratory consumables wholesale

- where can I find medical protection device

- where to buy hypodermic accessories

- where to buy medical apparel

- where to buy medical consumable accessories

- where to find OEM medical device supplier

- where to find rehabilitation equipment supplier