What is Good Manufacturing Medical Devices? GMP Explained

What is Good Manufacturing Medical Devices?

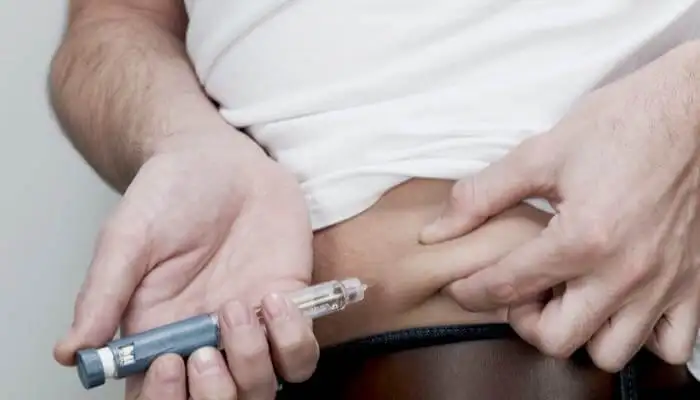

- The medical device industry is among the highly regulated industries in the world since it is associated with human life, safety, and well-being. Syringes, surgical tools, diagnostic supplies, infusion pumps, and blood pressure cuffs are not only products, but are fundamental tools that healthcare providers use on a day-to-day basis. In order to make the said devices safe, effective, and reliable, a stringent guideline referred to as Good Manufacturing Practices (GMP) should be followed by the manufacturers.

- Then, what is Good Manufacturing in the medical devices? To put it simplistically, it can be defined as a compilation of regulations, standards, and procedures to which the medical device companies are required to adhere to ensure the quality of products designed till their final delivery. These measures are taken to make sure that all devices coming out of a factory will be of GMO manufacturing and meet global regulatory standards, and finally offer safety to the patients.

Good Manufacturing Practice (GMP) in Medical Devices

What is good manufacturing medical devices? Good Manufacturing Practice (GMP) medical devices can be described as a process that encompasses all the areas of the manufacturing process in its quality assurance. Contrary to the general industrial production, GMP imposes very high standards of control of raw materials, validated processes, qualified equipment, trained staff, and strong documentation systems.

- The GMP medical device standards are not voluntary but rather mandatory for those manufacturers who are interested in selling their products worldwide. It could be the injection syringe, a diagnostic test kit, or a GMP-approved medical product such as an infusion pump; the rules are meant to bring about consistency and dependability.

- Fundamentally, medical device GMP compliance makes sure that the products, including devices, are always manufactured to quality, safety, and effectiveness standards as stipulated by the regulating bodies like the FDA, the European Union MDR (Medical Device Regulation), and the ISO certification agencies.

What Does GMP Mean in the Manufacture of Medical Devices?

- Design and Development Controls - All the devices have to be carefully risk-assessed and validated before hitting the market.

- Medical Device Production Standards - Raw material should be tested, equipment should be calibration, and the process should be controlled.

- Quality System Regulation (QSR) - Manufacturers should develop documented quality systems that are related to production, testing, and release.

- Risk Management of GMP Medical Devices - All possible risks should be identified and prevented by corrective and preventive measures.

- Medical Device Validation and Verification - Products and Processes. Medical devices and processes need to be subjected to thorough verification and validation to guarantee reliability.

- GMP Documentation Requirements - Documents should be prepared to be traced, and such documents are: batch record, test result, and change control.

This all-encompassing system provides the reliability of devices as a result of GMP, which creates confidence in healthcare providers as well as patients.

Comparison of ISO 13485 and GMP of Medical Devices

One of the most frequently mixed-up issues is the connection between the certifications of ISO 13485 and GMP compliance. Although they are similar, they are not the same.

- The ISO 13485 Certification is a standard of an international nature that outlines the specifications of the quality management system in the medical device business. It is concerned with constant improvement and the satisfaction of customers.

- GMP (Good Manufacturing Practices), on the other hand, is a code of lawful enforceable conditions that are put in place by the regulators, such as the FDA and the EU MDR. It is more concerned with the safety and effectiveness of devices.

Concisely, ISO 13485 deals with the development of an effective quality management system, whereas GMP guarantees regulatory compliance and enforcement. The two collaborate to ensure the safety and effectiveness of medical devices.

Significance of GMP in the Manufacture of Medical Devices

The role of GMP in the production of medical devices cannot be overestimated. It ensures that:

- The safety of the patients is ensured through reducing the risks of defects.

- Devices can be relied upon to work well by healthcare professionals.

- The regulators are also assured of the compliance of the manufacturers with safety laws.

- With GMP compliance, global trade is made easy because it enables market access.

Practically, GMP assists in the avoidance of cases of contamination, wrong labelling, or defective products. To patients, it will result in increased assurance of safety and efficacy of medical devices.

GMP in Quality Medical Devices Management

The management of the quality of medical devices is not only the process of complying with the requirements of the regulations, but also the creation of a continuous improvement culture. The regulation of the quality system for GMOs guarantees that each production process will lead to the general safety of the device. The purpose of GMP in the control of quality of medical devices involves:

- The risk should be minimized by ensuring the preventive measures in GMP systems.

- Ensuring the safety of products and GMP compliance in the international markets.

- Establishing a reliable building of devices with GMP leads to fewer recalls and failures.

- It confers on the healthcare providers a sense of confidence in the machines they work with daily.

The Role Played By GMP in Making Medical Devices Safe

GMP is based on safety. The way in which GMP makes medical devices safe can be viewed in several ways:

- Microbial or particulate contamination is avoided in cleanroom manufacturing.

- Validation and verification clarify that devices are used according to the intended use requirements.

- Risk management recognizes risks and puts up protective measures.

- Biocompatibility testing is done to ascertain the safety of materials to be used by humans.

- Traceability systems enable quick recall in case of any issues being identified.

The healthcare industry cannot do without GMP due to this all-inclusive safety net.

Conclusion

What is good manufacturing medical devices? It is a system of strict standards and procedures that guarantees safety, effectiveness, and conformity of devices to international regulations. With GMP manufacturing standards, companies will be able to provide the devices that bring trust, enhance healthcare outcomes, and protect patients. The Greetmed company is compliant with the regulations of the GMP quality system, which guarantees that all the products, including diagnostic equipment and surgical tools, are of a high international quality.

Submit Your Request

Recent Posts

Tags

- Adult Diapers

- Are custom medical devices safe

- Baby Diapers

- Can respiratory anesthesia be used

- Digital Healthcare

- Do you offer customized consumables

- European Market

- How do you take care of a skin wound

- Industry Trends

- Lady Sanitary Napkins

- Medical Devices

- OEM Medical Devices

- Product Introductions

- Protective Equipment

- Under Pads

- What are custom-made medical devices

- What are diagnostic products

- What are hospital dressing products

- What are medical tube catheters

- What are some common protective equipment

- What are the appropriate applications for hospital dressing products

- What are the appropriate uses for protective equipment

- What is a gynecological examination

- What is a medical consumable

- What is an anesthesia kit

- What is an OEM in medical devices

- what is an wound skin care

- what is can disposable ultrasonic diagnostic

- What is good manufacturing medical devices

- What is hospital-grade protective equipment

- what is medical equipments hospital furniture

- What is medical sterilization wrapping

- What is rehabilitation equipment device

- What medical consumables do you supply

- Where can I find laboratory consumables wholesale

- where can I find medical protection device

- where to buy hypodermic accessories

- where to buy medical apparel

- where to buy medical consumable accessories

- where to find OEM medical device supplier

- where to find rehabilitation equipment supplier