Why Frontliners Rely on Hospital-Grade Protective Gear

Hospital-Grade Protective Gear is more than a line item in a supply budget - it is the invisible shield that lets doctors, nurses, respiratory therapists, and emergency responders step into danger and come out healthy. At Greetmed, we witness that quiet heroism every day: the gown that blocks an aerosolized pathogen, the respirator that holds a patient's last hope, the glove that keeps infection from leaping host to host. Serving those frontliners is our single focus, and it shapes everything from the fibers we weave to the way we fulfill a late-night rush order.

Why Hospital-Grade Protective Gear Matters

Healthcare shifts are unpredictable, but the threats are constant. Pathogens mutate, procedures grow more complex, and workplace fatigue creeps in. Only true Hospital-Grade Protective Gear stands up to all three challenges at once.

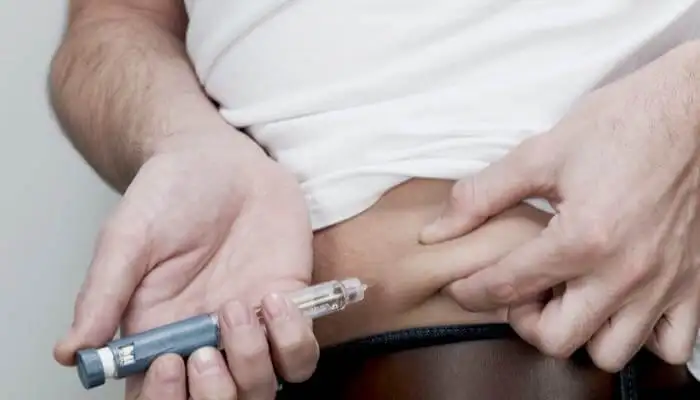

Every item we manufacture - scrubs, lab coats, isolation gowns, protective coveralls, and the essential surgical gown - is cut from antimicrobial fabric that resists fluid penetration without sacrificing breathability. Stretch panels at stress points let a nurse bend, lift, or sprint without a gown tearing at the seam. Smooth, hypoallergenic linings reduce skin irritation, so clinicians can forget about their clothing and focus on the patient before them.

When frontliners trust their equipment, decision-making sharpens. They communicate calmly, move decisively, and complete procedures faster. Safety ripples outward: fewer hospital-acquired infections, fewer staff sick days, and ultimately fewer families facing heartbreak. That chain of benefit begins with gear built to hospital standards and tuned by people who build it every day.

Designing Hospital-Grade Protective Gear

Our design process starts with a question that sounds simple: How will this product feel six hours into a double shift? The answer drives a cycle of material science, ergonomic testing, and field feedback that never really ends.

• Choosing Materials That Protect and Breathe

We layer spun-bond polypropylene with melt-blown filtration, then ultrasonically seal seams to eliminate needle holes. Yet a foil-thick gown is useless if the wearer overheats. That is why we interlace micro-mesh vents along the spine and underarms - zones where body heat peaks. Bench tests confirm barrier performance, but we also run wearer trials in our mock ward, monitoring core temperature and humidity so we can tweak panel placement until comfort and safety meet.

• Listening to the People Who Wear It

We invite ICU nurses, anesthesiologists, and ambulance crews into our prototyping studio. They pull, twist, and splash liquids on samples while narrating their pain points:

"The thumb loop on my current gown tears by lunchtime."

"I need a hood that fits over my stethoscope and still seals."

"My coverall zipper jams when I'm sweaty."

Their critiques become our to-do list. Every loop is double-stitched, every hood integrates a stethoscope port, and zippers receive an internal storm flap that glides even under condensation. Field testers then run a full shift in the updated design, logging comfort scores and snag counts in a cloud app we built for real-time feedback. Only when wearers rate an item 4.8/5 or better do we certify it as Hospital-Grade Protective Gear.

• Integrating Fast Production With Global Standards

Once a prototype graduates, it moves to automated cutting tables synchronized with our ERP system. Each gown or mask is labeled and recorded in a system that ensures full product traceability from polymer batch to shipping carton. That transparency earns us ISO 13485 certification year after year, and it lets hospitals audit our supply chain with two clicks.

Partnering With Greetmed

We believe our gear's journey does not end when it clears the final inspection; it ends when a frontline worker reaches for it in a crisis and finds it exactly where it should be. To make that happen, we align production capacity, warehousing, and customer service around five promises:

✅ Fast delivery time - strategically located hubs cut transit days, not corners.

✅ Effective solutions - cross-functional teams pair infection-control experts with logistics analysts to solve unique supply puzzles.

✅ Trustworthy communication - every client gets a dedicated rep with 24-hour response SLA, because unanswered messages cost lives.

✅ Dependable quality - our inline vision systems flag defects in real time; nothing questionable leaves the floor.

✅ Reliable order fulfillment - predictive analytics balance raw-material inventory so surges of demand do not empty shelves.

Beyond operational excellence, we hold a north-star mission: "Make every corner of the world be full of love, and every family in the world healthy.” That mission powers outreach programs where we donate surplus Hospital-Grade Protective Gear to rural clinics and disaster zones. It also guides our sustainability roadmap - from energy-efficient lamination lines to recycling partnerships that turn post-use gowns into non-woven insulation.

Frontliners will keep facing new pathogens, novel procedures, and the timeless pressure of saving lives under fluorescent lights. Our role is not merely to sell them gowns, masks, and tubes. It is to anticipate their next challenge and meet it with gear so trustworthy they can forget it exists. We greet each dawn with that commitment woven into the fibers we spin and the promises we keep. When the next urgent call comes, we want every clinician to suit up, breathe easy, and remember that someone, somewhere, is watching their back.

Greetmed: greeting the day, greeting the future - one piece of Hospital-Grade Protective Gear at a time.

Submit Your Request

Recent Posts

Tags

- Adult Diapers

- Are custom medical devices safe

- Baby Diapers

- Can respiratory anesthesia be used

- Digital Healthcare

- Do you offer customized consumables

- European Market

- How do you take care of a skin wound

- Industry Trends

- Lady Sanitary Napkins

- Medical Devices

- OEM Medical Devices

- Product Introductions

- Protective Equipment

- Under Pads

- What are custom-made medical devices

- What are diagnostic products

- What are hospital dressing products

- What are medical tube catheters

- What are some common protective equipment

- What are the appropriate applications for hospital dressing products

- What are the appropriate uses for protective equipment

- What is a gynecological examination

- What is a medical consumable

- What is an anesthesia kit

- What is an OEM in medical devices

- what is an wound skin care

- what is can disposable ultrasonic diagnostic

- What is good manufacturing medical devices

- What is hospital-grade protective equipment

- what is medical equipments hospital furniture

- What is medical sterilization wrapping

- What is rehabilitation equipment device

- What medical consumables do you supply

- Where can I find laboratory consumables wholesale

- where can I find medical protection device

- where to buy hypodermic accessories

- where to buy medical apparel

- where to buy medical consumable accessories

- where to find OEM medical device supplier

- where to find rehabilitation equipment supplier